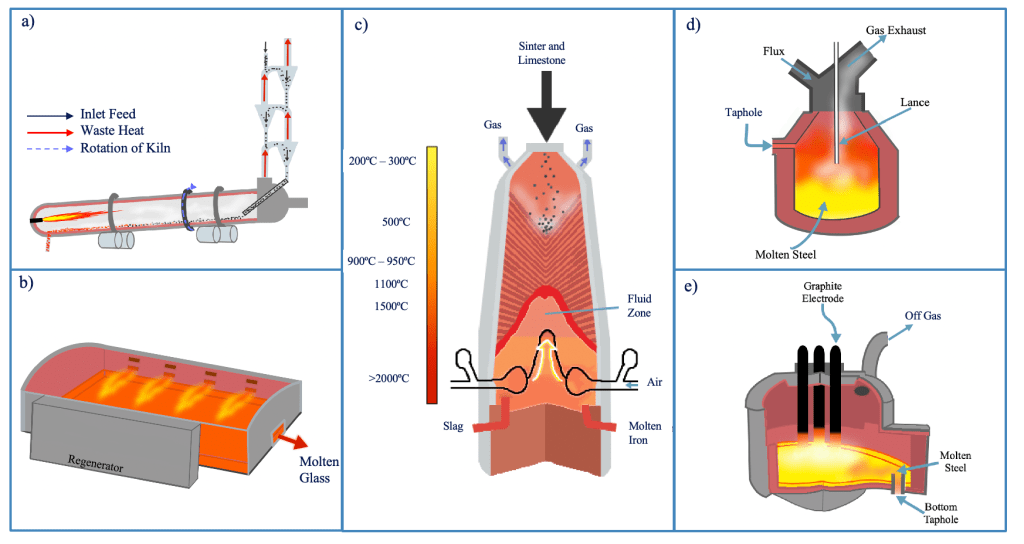

Incumbent industrial kiln and furnace technologies with a) rotary kiln, often used in cement or lime production, b) hearth furnace used in glass making, c) blast furnace used in iron and steel production, d) basic oxygen furnace used in iron and steel production, and e) electric arc furnace used in iron and steel recycling and production.

Advisor: Dr. Jennifer Wilcox, Chemical Engineering and Energy Policy, University of Pennsylvania — Clean Energy Conversions Laboratory

This research is focused on analyzing innovative pathways to address the carbon dioxide (CO2) emissions that result from industrial activity. For this project, the U.S. was the focus based on the locational data available and the decarbonization roadmapping that could be interpreted based on it. However, it is expected that any innovative technological pathway for decarbonization in the cement, lime, glass, or iron & steel industries could be adopted outside of the U.S. as well.

The IPCC recommends that to keep average global temperature rise below 2ºC by 2100, carbon neutrality must be achieved shortly after 2050. In the United States, industrial emissions represent 22% of greenhouse gas emissions and are particularly hard to decarbonize, because (1) the processes emit CO2 as a byproduct of chemical reactions and (2) these industries require high-grade heat input. This work details the kiln and furnace technologies that are used in the cement, lime, glass, and iron & steel industries today and explores emerging processes, with examples of existing projects, that aim to reduce CO2 emissions. The innovative pathways for decarbonization include carbon capture and storage (CCS), fuel switching with biomass and hydrogen, and other technological changes. In addition, two states (California and Pennsylvania) within the U.S. with high concentrations of industrial activity are analyzed on a geospatial basis, highlighting co-located opportunities for the adoption of these decarbonization pathways.